Post-Manufacturing Services

We provide full-service solutions that go beyond manufacturing, ensuring your product’s success throughout its lifecycle. From new product introduction to end-of-life support, our post-manufacturing services cover everything from order fulfillment and field service returns to product upgrades and inventory management.

Order Fulfillment

We simplify your supply chain by offering end-to-end order fulfillment solutions tailored to your business needs. Avoid the cost and complexity of setting up infrastructure by leveraging our capabilities, which include:

Our comprehensive testing ensures:

- Accurate component placement and connections

- Defect detection early in production

- Consistent performance and durability under all conditions

Call us : (208)-850-6232

Automated Optical Inspection (AOI):

AOI ensures quick, accurate detection of surface-level defects like missing components, solder issues, polarity problems, and misalignment.

In-Circuit Testing (ICT)

ICT verifies electrical performance, checking for shorts, opens, and correct component values to ensure functional integrity.

Functional Testing (FCT)

Simulating real-world conditions, FCT verifies the overall functionality of the PCB under operating parameters.

X-Ray Inspection

X-ray technology allows us to inspect hidden solder joints, such as BGA components, ensuring accuracy in complex assemblies.

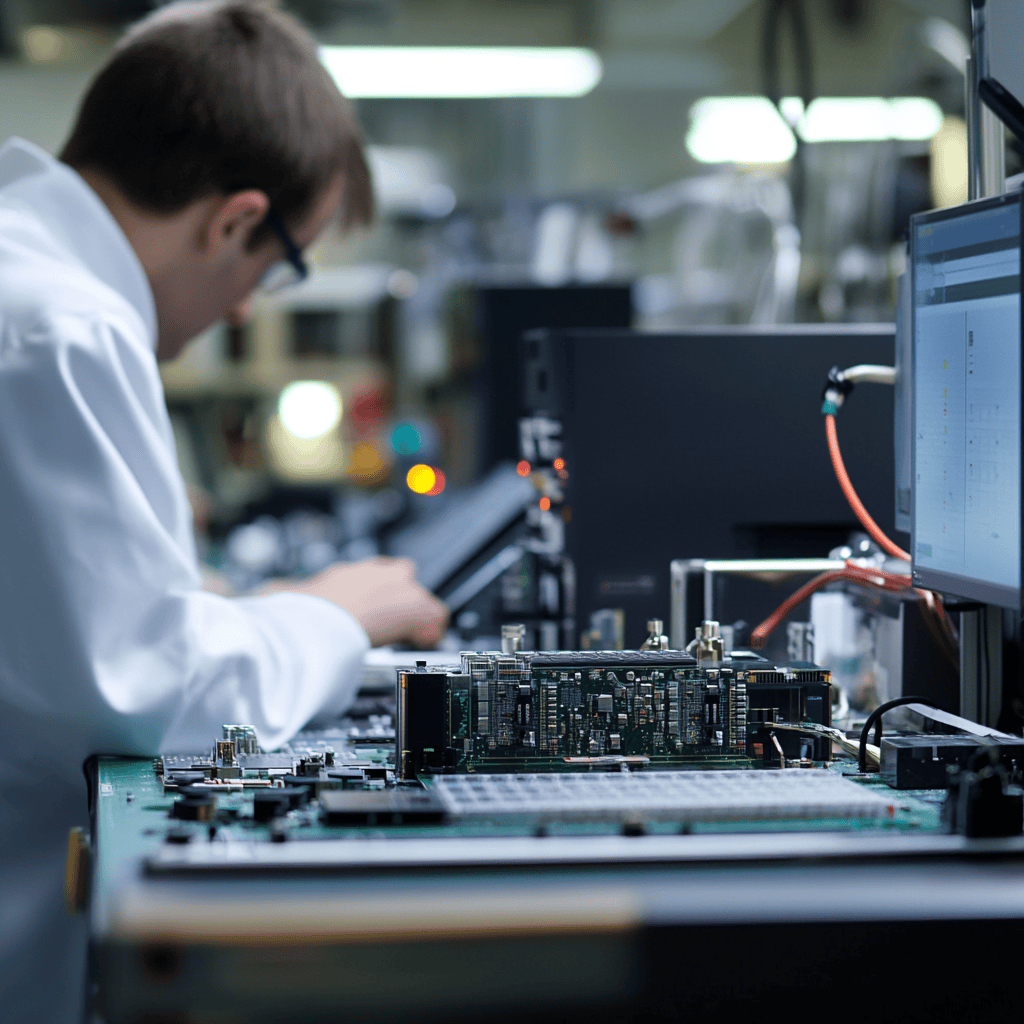

Cutting-Edge Testing for Unmatched Quality Assurance

Our PCB Testing Capabilities

We utilize advanced tools and techniques to conduct thorough testing, ensuring every PCB meets the highest performance standards.

Benefits of Our Testing Approach:

- Faster defect detection and correction

- Enhanced product lifespan and performance

- Reduced production delays and failures

A Streamlined Process for Superior Results

Our Testing Process

At Elexceltek, our testing process combines efficiency and precision to deliver the highest quality results:

Our Prototyping Services Include:

Pre-Testing Inspection

Each PCB undergoes visual and automated inspections to catch obvious defects early in the production cycle.

Automated Optical Inspection (AOI)

Using advanced AOI systems, we detect solder issues, missing components, and alignment errors with high accuracy.

Functional and In-Circuit Testing

PCBs are tested for electrical performance and functionality using customized testing equipment to meet your project’s requirements.

Final Quality Verification

X-ray and other validation processes ensure hidden solder joints and connections meet standards before final delivery.

Perfecting Designs Through Rapid Prototyping and Testing

Prototyping and Testing

Why Choose Our Prototyping and Testing Services:

- Early defect detection and correction

- Optimized performance before mass production

- Faster time-to-market for your products

Your Trusted Partner for Quality and Reliability

Why Choose Elexceltek for PCB Testing?

When you choose Elexceltek, you benefit from:

- Advanced Testing Capabilities

- Expert Engineers

- Custom Solutions

- Reduced Defects

- Scalable Services